Metal edging is a practical and durable solution for creating clear divisions across landscape features. It plays a crucial role in defining spaces, preventing material migration, and supporting long-term maintenance. At Bret-Mar Landscape, we apply a range of metal edging options in both modern and traditional settings, where form and function must coexist through all seasons.

Whether used to separate gravel from lawn, control soil around planting beds, or reinforce the edge of a hardscape, metal edging performs reliably under the pressures of climate, equipment, and foot traffic. Each material serves different structural needs, and correct selection depends on application, layout, and the surrounding elements in a given yard.

Applications of Metal Edging in Landscape Design

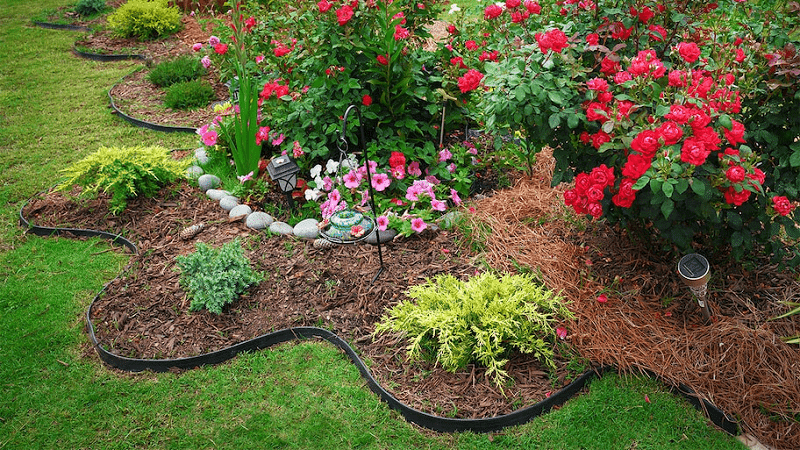

In a complete landscape design, metal edging helps delineate areas without obstructing visual flow. This is especially important in spaces where multiple surfaces intersect—pavers, turf, concrete, or decorative stone.

When installed between mulch and perennial beds, edging holds material in place and prevents grass from creeping into garden zones. Along a driveway, it provides a clean margin that reduces rutting and protects against tire erosion. Around a kitchen garden, edging defines planting geometry while containing herb rows and soil structure.

Metal boundaries are essential when integrating mechanical equipment into a landscape. For instance, they help guide mower wheels, reduce interference with string trimmer use, and prevent loose leaf debris from building up in unintended areas. These lines also support drainage plans, helping redirect water away from foundations and other critical areas during storms.

Weathering Steel for Structural and Aesthetic Durability

Weathering steel develops a protective layer of surface oxidation that resists further corrosion, forming a natural patina that stabilizes over time. This makes it especially well-suited for high-moisture environments and projects that require structural edge retention with minimal visual interference.

In Chicagoland installations where temperature swings and seasonal precipitation test material limits, weathering steel consistently maintains alignment. It is especially useful in deep trench applications along turf edges or when installed to contain gravel beside poured concrete walkways. Its visual properties allow it to fade into natural surroundings while still contrasting cleanly against elements like wood decking, fence posts, or decorative boulders.

This material supports projects designed to emphasize eco-friendly outdoor materials, particularly where minimal coatings or finishes are desired and aging is seen as a design feature rather than a defect.

Galvanized Steel for Functional Bordering

Galvanized steel is protected by a zinc coating that inhibits oxidation, making it a smart choice for residential installations where consistency and resistance to weather are priorities. It’s often used in areas of repeat edge contact—mowers, carts, and foot traffic—because of its durability and ability to maintain a straight line.

In applications bordering perimeter beds, fence bases, or raised shrub groupings, galvanized steel provides a smooth, neutral finish that allows other landscape features to stand out. It bends cleanly for use in curved layouts and resists denting under pressure from light equipment or seasonal shifts in soil density.

This material is also frequently paired with automatic sprinkler system installation to reduce edge displacement near irrigation lines and maintain control over run-off zones without shifting.

Cast Iron and Decorative Iron for Visual Weight

Cast iron edging offers high structural integrity and is frequently specified in installations that require permanence and ornamental value. Its weight anchors it in place, even in unstable soil or sloped zones where lighter materials may heave or shift over time.

Used along formal garden borders, curbs, or older home foundations, cast iron contributes to the architectural language of the landscape. It works especially well with copper downspouts, wood trellises, and other natural finishes that develop visual character over time.

We install cast iron most often in front-yard projects that incorporate landscape design elements intended to coordinate with historical or stone-faced structures. Surface finishes are applied to limit oxidation, but in cases where natural aging is desired, raw iron surfaces may be left exposed.

Lightweight Metal Options for Decorative Borders

While heavier edging materials offer strength and permanence, certain conditions call for metals like aluminum or copper, especially when the priority is flexibility or reduced weight. These materials are suitable in installations involving low-traffic garden design, interior yard divisions, or purely visual enhancements.

Aluminum resists corrosion and offers easy shaping for irregular borders. It performs well in herb beds or raised planting boxes where trenching is shallow and soil pressure is minimal. Copper, though more costly, brings aesthetic variation that evolves over time. Its naturally occurring green-blue oxidation layer offers visual variety against mulch, stone, and shrub foliage.

Both materials are best applied in protected zones—away from heavy wheels, snow loads, or deep root systems. Their primary advantage lies in appearance and ease of installation, not structural capacity.

Installation Standards and Site Coordination

Proper installation determines whether metal edging will perform over time. Depth, anchoring, and spacing all influence the outcome. For example, in trench installations alongside driveways, metal must be embedded deeply enough to resist vehicle-induced pressure and supported with long-term fastening systems.

When edging is integrated near sprinkler systems or electrical lines, layout coordination must occur during initial excavation. This helps avoid damage and ensures that components like pavers, curbs, or utility features remain structurally isolated.

We account for surface grading, equipment clearance, and seasonal frost cycles in every edge layout. Where edging borders vegetation, material choice also factors in compatibility with nearby perennials, moss, or shallow-rooted grasses. We avoid fast-degrading metals in irrigation-heavy areas or locations with extreme pH conditions in the soil.

All installations align with long-term maintenance goals, minimizing the need for repairs, adjustments, or seasonal resets.

Material Selection Based on Landscape Context

Selecting the correct metal edging is not just a technical choice—it reflects the priorities of the overall landscape. When visual aging is desired, weathering steel develops gracefully under exposure to air and water. Where finish integrity is paramount, galvanized steel offers uniformity and performance. In applications where weight and resistance matter most, cast iron delivers. And where detail and form flexibility are the focus, copper or aluminum may be used selectively.

Each of these materials has a different relationship to adjacent surfaces and climate exposure. In full-scope designs that involve elements like paver patios, mulch beds, and custom plant layouts, material consistency supports both function and visual continuity.